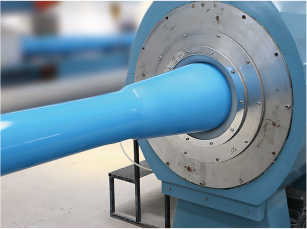

The Oule production line is mainly used for the production of PVC-O pipes, with pipe specifications of DN75-1000mm.Our company can provide a complete set of PVC-O production lines and technologies,Welcome friends from all walks of life to inquire!

Tel: +86 139 3080 8229

email:olivepipe@163.com

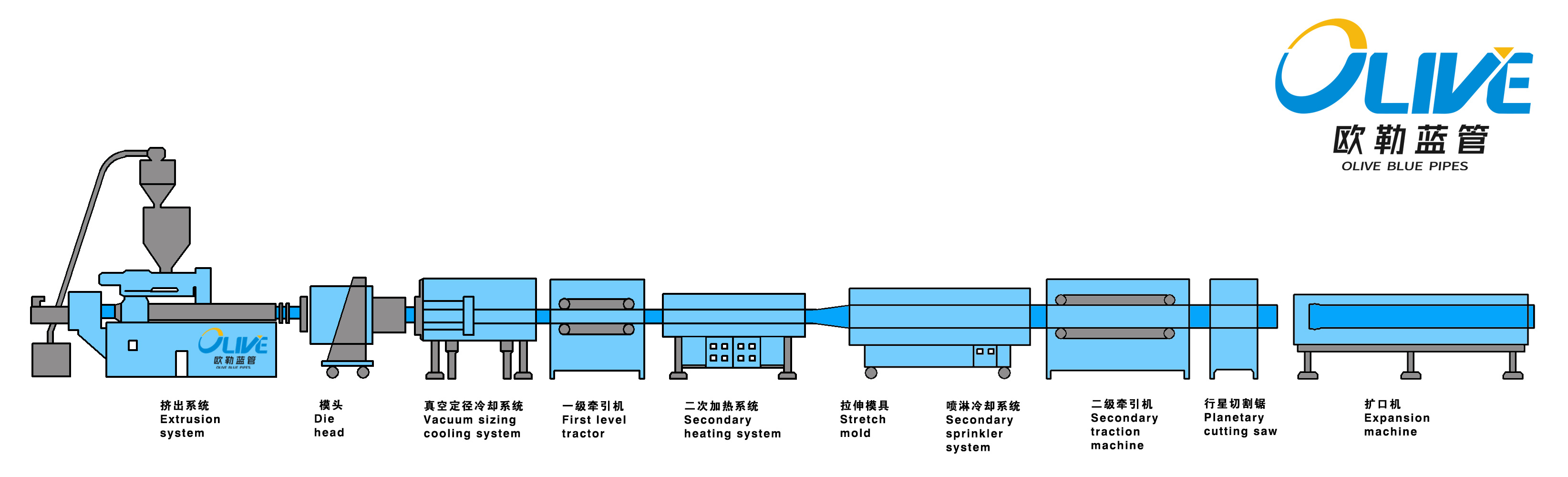

Performance of equipment in each unit of PVC-O production line

1. Extrusion system:

Special screw design, uniform material mixing, good plasticizing effect, stable output

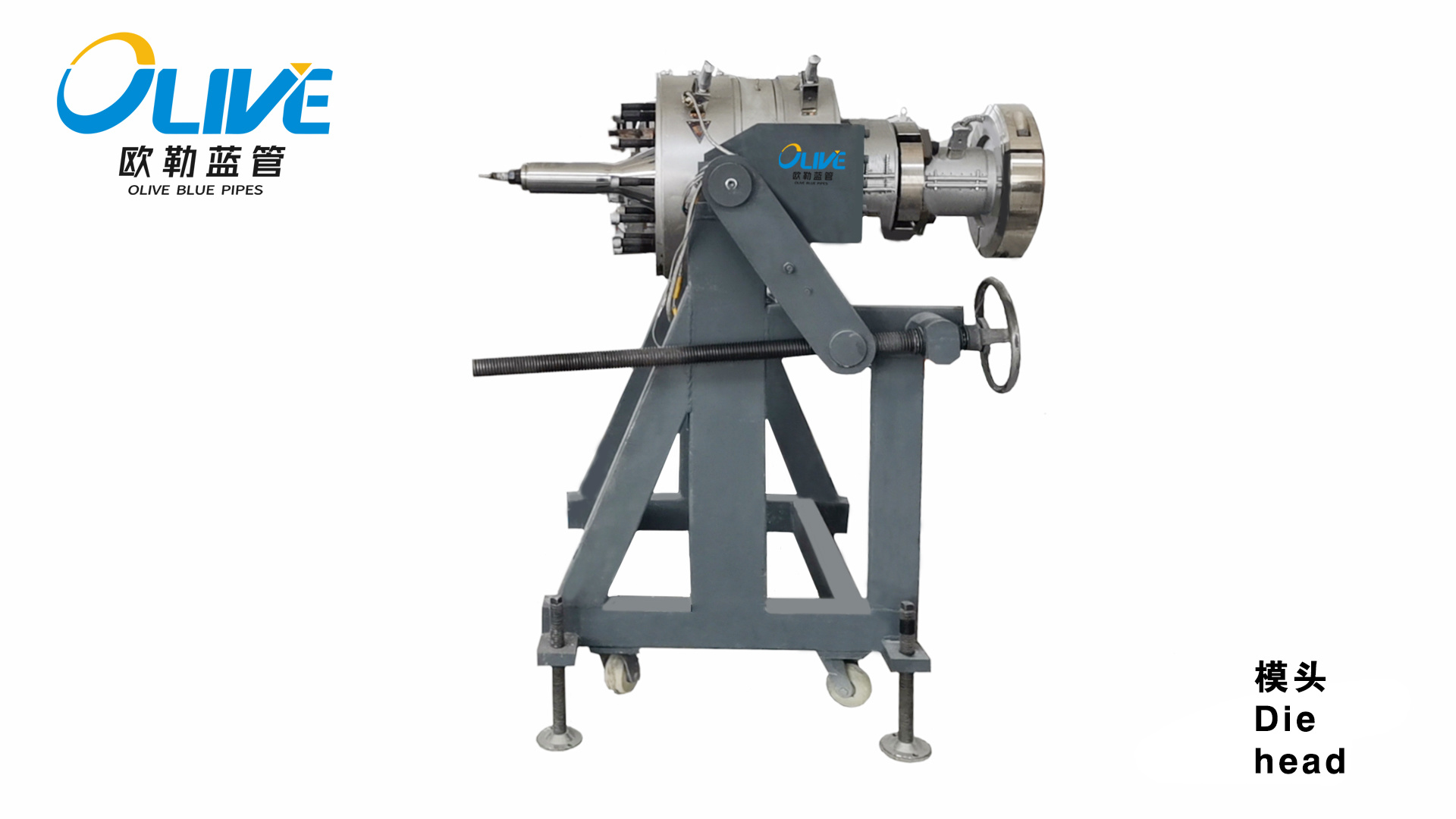

2. Die head:

Unique structure and channel design ensure even distribution of melt and high molding quality

3. Vacuum sizing cooling system:

Adopting a stainless steel 304 casing, the inner surface of the sizing sleeve has been specially treated for high dimensional accuracy; The surface of the pipe is smooth; Accurate control of water temperature

4. First level tractor:

Variable frequency precise speed control; The track adopts high wear-resistant traction rubber blocks, which do not slip

5. Secondary heating system:

No dead angle hot air circulation, uniform heating of the pipe wall, temperature control accuracy ± 1 ℃

6. Stretch mold:

The special cone structure design, supplemented by an external pressure source, is very easy to stretch; High stretch ratio and high pipe strength

7. Secondary sprinkler system:

Multi angle spray, high cooling efficiency

8. Secondary traction machine:

Strong traction, precise speed

9. Planetary cutting saw:

High cutting efficiency, smooth and neat incision, no burrs, low noise

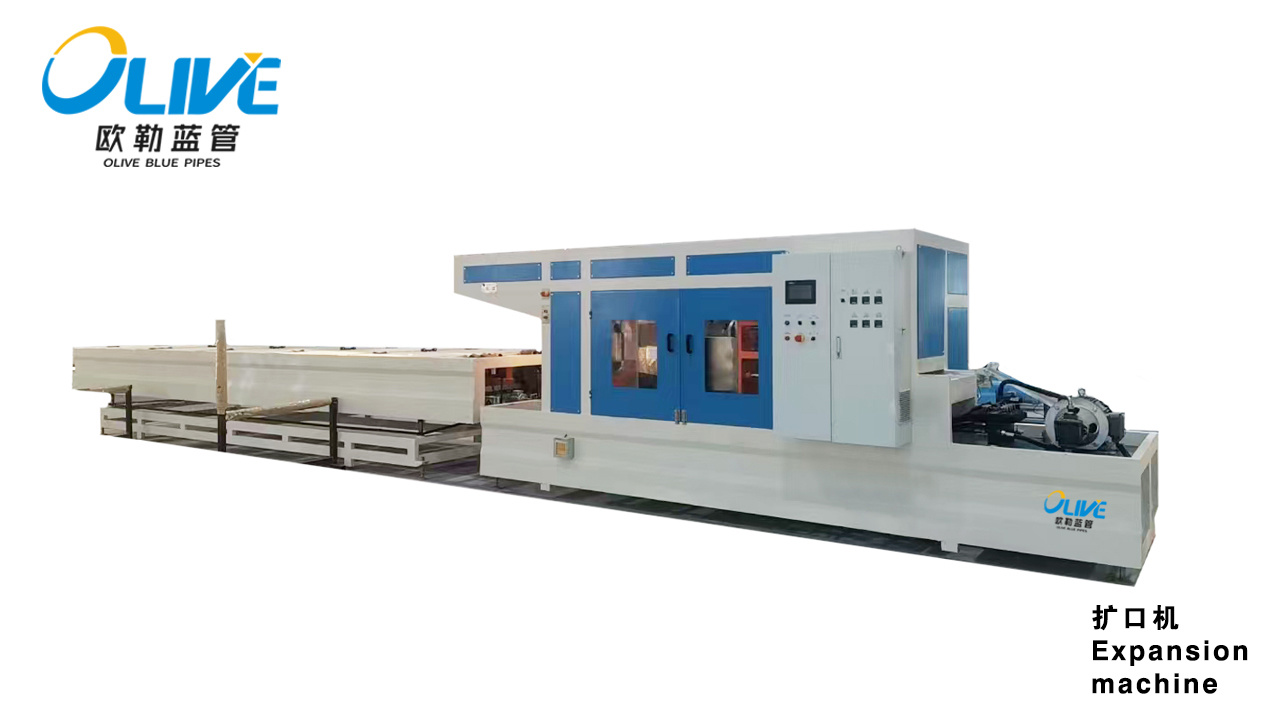

10. Expansion machine: Far infrared heating, precise temperature control, high molding accuracy